Peters Rubber & Plastics has a state-of-the-art assembly line with various flexible possibilities

Assembly line

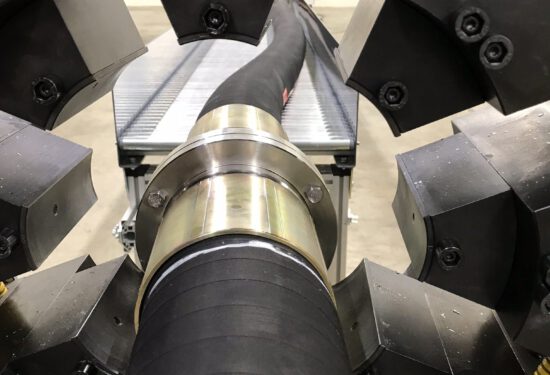

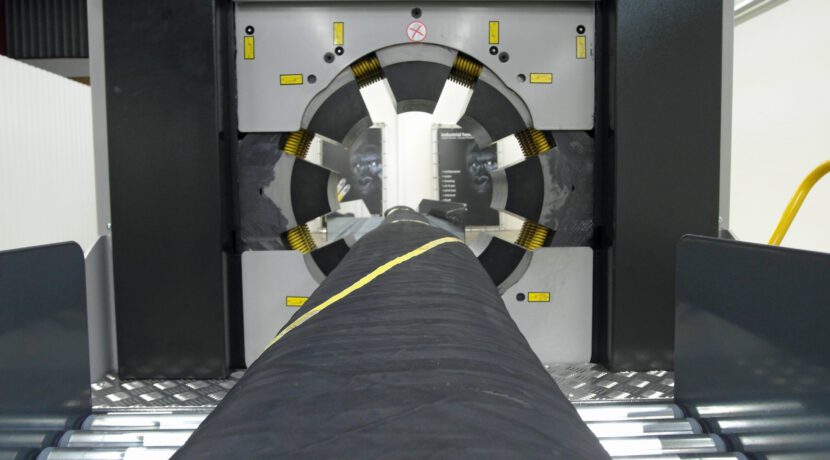

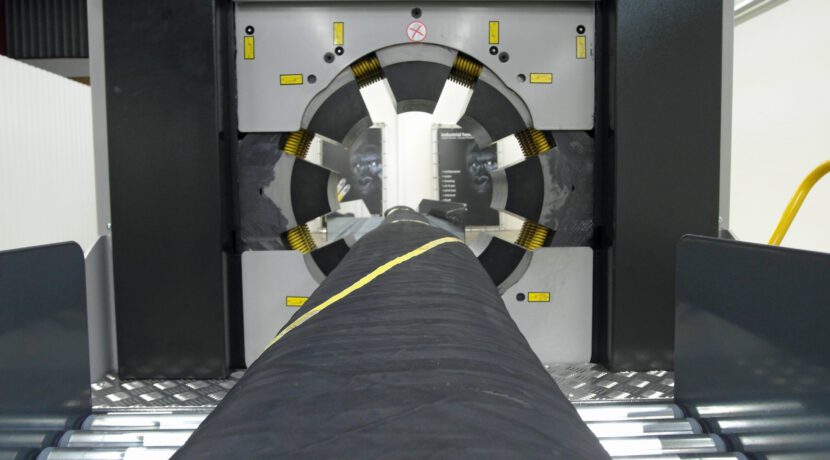

Crimping machine

- Max. capacity: up to 12″ Flanges

- Crimp force: 550 tons

Automatic saw

- Max. diameter: 8″

Resato test units

- Computer controlled and linked to TESSALINK Hose Mangement System

- Unit #1 test pressures up to 150 Bar for large bore industrial hose

- Unit #2 multiple manifolds, hose up to 2 inch and pressures up to 1200 Bar

- automatically generated test reports with grafics

Lasermarking

With our laser marker we can imprint customer-specific markings on ferrules or ID-tags:

- Unique batch number

- Temperature range

- Pressure range

- Electrical conduction

- Production date

- QR-Codes

- Logos

Assembly work at Peters

Assembly: On way to Africa

We have received a splendid opportunity for an assembly task for an end user in Nigeria.

Our client needed a 50mm ContiTech chemical suction and discharge hose according EN 12115 in multiple 3 and 2 meters, with 3” SS flanges and TODO hose units.

We delivered all 26 Continental ContiTech Fabchem EN 12115 hoses with laser engraved marking on the couplings, 26 test rapports and a certificate of conformity.

Assembly: Quantity with quality

We received a challenging enquiry from one of our customers involving 27 hoses for subsea application. We had to tackle some issues concerning the application and the engineering of the hose assembly. Each coupling has a laser-marked imprint of the hose and assembly specifications.

We took a prototype of the batch which has been burst pressure tested (to 4:1 safety factor of hoses for integrity of the coupling). We have done a destructive- and leak test according to ISO EN1402.

We managed to finalize the entire assembly process within the desired delivery time of one week.